Products and services

contact

Contact us for tailored solutions: our team is at your disposal to meet every need with competence, quality, and speed.

CONTACT FORM

Error: Contact form not found.

contact

Contact us for tailored solutions: our team is at your disposal to meet every need with competence, quality, and speed.

CONTACT FORM

Error: Contact form not found.

Machining processes.

Our continuously evolving amusement park machinery combines technological innovation and ongoing training to consistently deliver quality and precision every time.

Multitasking technology

The Integrex multitasking technology combines milling and turning into a single machine, reducing production times and increasing efficiency. It is ideal for complex components ensuring high position, flexibility and quality We can work up to Ø710 x 2000 mm

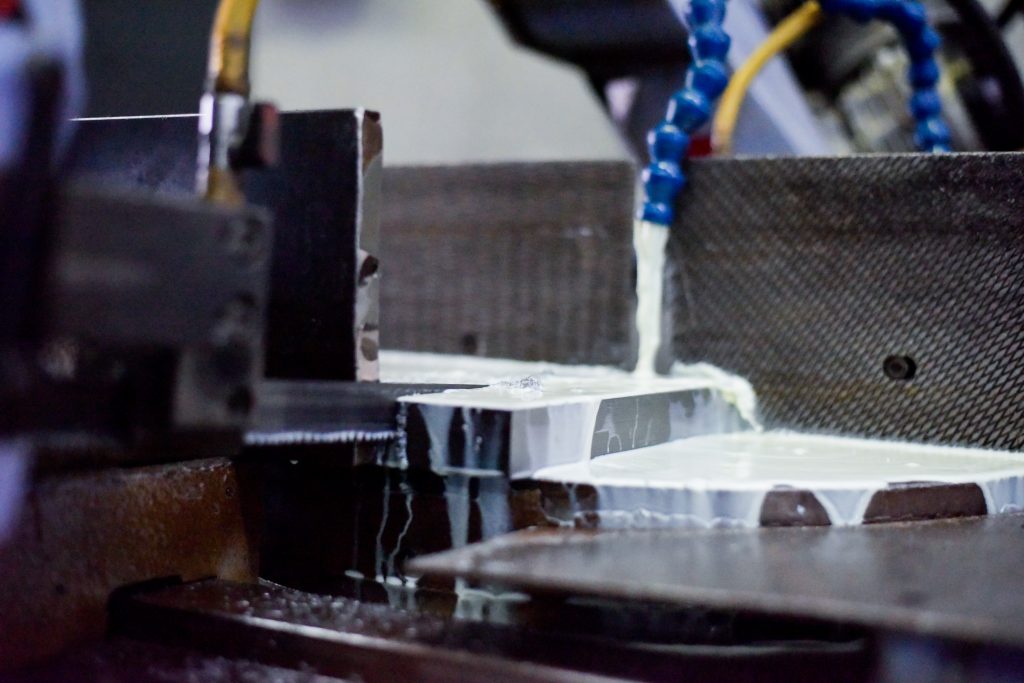

Milling

We are capable of working up to 710×2000 mm, with three, four and five axis capabilities, offering maximum travel of 1650 mm x 530 mm times 510 mm. Additionally, we have a horizontal machine with a pallet changer (760×760×810 mm) both equipped with CAD/CAM. We offer precise and optimized milling services, meeting every requirement. Advanced control systems ensure the highest precision and optimization of

Turning

We offer a precision CNC contour Turning, working with diameters up to 8350 mm in length up to 2000 mm. We invest in advanced technologies to ensure high-quality semi finished products and to meet specific request with precision and efficiency

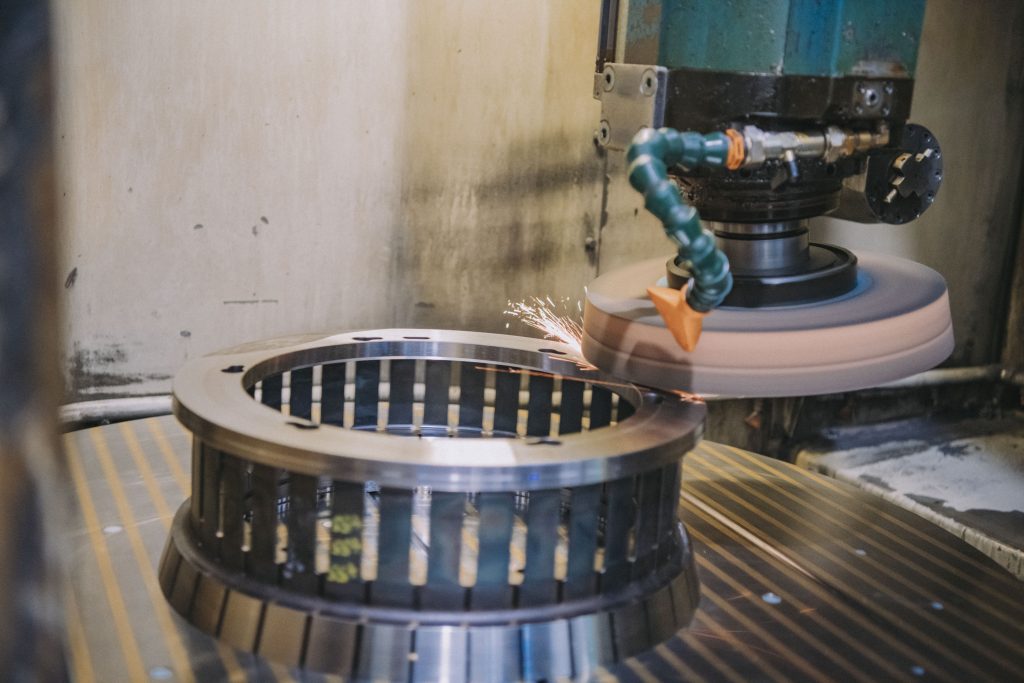

Grinding

We carry out internal external and surface grinding using skilled operators in advanced machinery. Precision and quality are guaranteed to reach high standards even in the most complex mechanical constructions. the maximum travels are for cylindrical grindingØ 450×1500 mm, vertical grinding Ø1200 x 650mm e surface grinding 1600 x 600 x 500 mm)

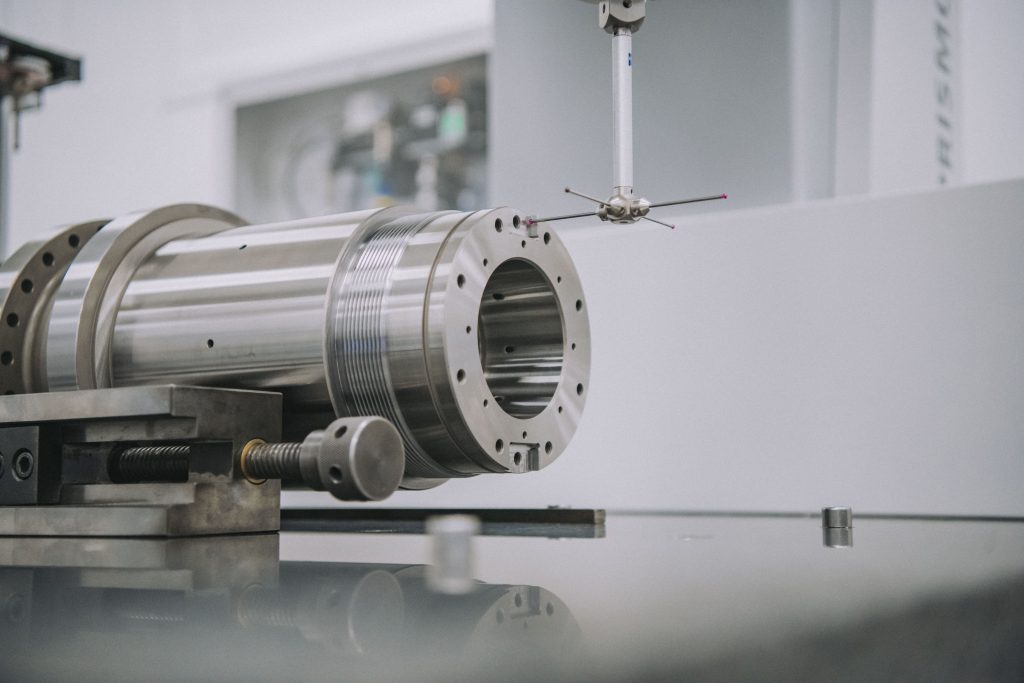

Inspection according to Control plans

We have two metrology rooms maintained at a constant 20°C. We use advanced 3-D measuring machines and roundness testers for rigorous inspections. Our quality controls are tailored to specific requirements, ensuring maximum precision and quality for every product .

Dedicated assembly room

Our team assembles mechanical units to test the functionality and run out of components. The assembly room, inaugurated in 2018 ensure accurate testing of semi finished products and electro spindles

Material cutting

We use advanced technologies for material cutting, ensuring extreme precision and optimization. Every process is designed to guarantee efficiency in the highest quality of the final product

EDM machining

thanks to EDM, we manufacture components of any geometric shape using a wire electrical discharge machining EDM (600 x 400 x 425), immersion (500x350x350) and microdrill (350x250x330) ensuring maximum precision and results that are impossible to achieve with other technologies .

Heat treatments / surface coatings

we collaborate with qualified partners for heat treatments such as hardening, carburizing, and nitriding, as well as coatings including natural and thick anodizing, PVD coating, hard chroming, phosphating, chemical nickel plating, electroplating, ceramic coatings, ensuring the highest quality and resistance

Cad Cam designs

We use advanced CAD/CAM software to convert client files into error free programs, optimizing time and quality while reducing margins of error. Our technical team is constantly trained on the latest developments .

Complementary Processing

Laser Marking

This operation allows marking flat or curved surfaces without damaging the structural integrity of the component itself. We create QR codes, barcodes, company logos, an identification numbers to meet

Balancing

We perform balancing operations to balance rotating elements up to Ø130 mm ,improving functionality while reducing vibrations, noise, and mechanical stress. We guarantee high precision and operational efficiency of the components

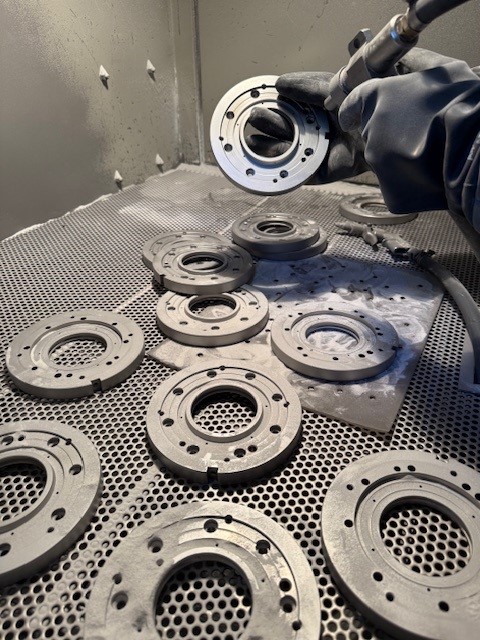

Sand blasting

using a pressure sandblasting machine, we offer surface cleaning and preparation, removing residues and smoothing surfaces. We customize the treatment to meet both aesthetic and functional requirements with various techniques

Fitting and visual inspections

Fitting on the workbench is the final art of the machining process. It requires position, skill, and attention to transform the parts into products that conform to the executed design, whether pre-or post heat treatment, ensuring flawless results .

Custom machining and high precision

Our wide range of services, from design to final production, guarantees quality and precision at every stage. Each service is customized to meet your specific needs.

contact

Contact us for tailored solutions: our team is at your disposal to meet every need with competence, quality, and speed.

CONTACT FORM

Error: Contact form not found.